Ngokufaka i-carbide, ukukhetha kunzima futhi kunzima

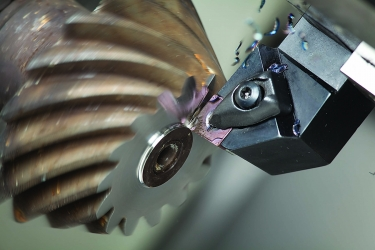

Ekuqaleni kokuphophoma, ubulukhuni nokuqina kungase kubonakale njengemiqondo eshintshashintshayo, kodwa zikhona emaphethelweni ahlukene wokuqhubeka okuchaza ukufakwa okunenkomba nokusebenza kwethuluzi lokusika eliqinile, ikakhulukazi uma kuziwa ekufakweni kwe-carbide. Izingxenye eziqinile zinikeza ukumelana okukhulu nokugqokwa kokusebenza okuthuthukisiwe nempilo yamathuluzi ezindaweni zokusika ezishisayo kunokufakwa okuthambile ngandlela-thile, nokho ukufaka okuqinile kungamelana nemithelela kanye nezingcindezi ukuze kuzuzwe amazinga aphezulu okuphakelayo nama-DOC.

Kunoma isiphi isicelo, kukhona ukulingana okuphelele kokuqina nokuqina - futhi abenzi bamathuluzi basebenze ngokuzikhandla ukuze basungule imigomo ye-metallurgical futhi banikeze uhla lwamathuluzi angahlangabezana nezidingo ezihlukahlukene zabakhiqizi bezingxenye.

Ukuqina kumelela ukumelana nokugqoka, okuhumusha ikhono lethuluzi lokumelana nokushisa ngesikhathi sokusika insimbi. Isikali se-Rockwell A sikala ubulukhuni be-tungsten carbide, nakuba ezinye izincazelo zihumusha amanani e-HRA kusikali esijwayeleke kakhulu se-HRC esisetshenziswa ukukala ubulukhuni bensimbi namanye ama-alloys. Ukumelana nezinga lokushisa okuhambisana nobulukhuni kudlala indima enkulu ekusikeni ukuziphatha kwamathuluzi nasekukhetheni.