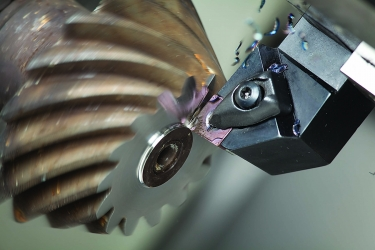

With carbide inserts, the choices are hard and tough

At first blush, hardness and toughness may seem like interchangeable concepts, but they exist at opposite ends of a continuum that defines indexable insert and solid cutting tool performance, particularly when it comes to carbide inserts. Hard inserts offer greater wear resistance for enhanced performance and tool life in hot cutting environments than somewhat softer inserts do, yet tough inserts can withstand impacts and stressors to achieve high feed rates and DOCs.

For any given application, there is an optimal balance of hardness and toughness — and toolmakers have worked diligently to establish metallurgical principles and provide a range of tools that can meet the diverse needs of part manufacturers.

Hardness represents wear resistance, which translates to the ability of a tool to withstand heat during metalcutting. The Rockwell A scale measures the hardness of tungsten carbide, though some specifications translate HRA values to the more familiar HRC scale used to measure the hardness of steel and other alloys. The temperature resistance that correlates with hardness plays a huge role in cutting tool behavior and selection.